Metallische Dünnschichtsensor Ausgewählte Artikel

Metallische Dünnschichtsensor Ausgewählte Artikel

- Chapter 1

- Introduction

Leveraging our refined proprietary sensing technologies, we contribute to the creation of innovative products in various fields by harnessing the high-performance potential generated by this technology.

Types of Strain Sensors

(1) Resistance Foil Strain Sensor

(2) Semiconductor (Si-MEMS) Strain Sensor

(3) Thin Film Strain Sensor

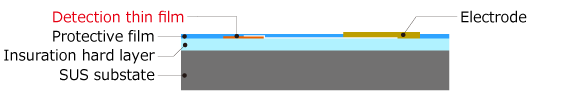

What is a Thin Film Strain Sensor?

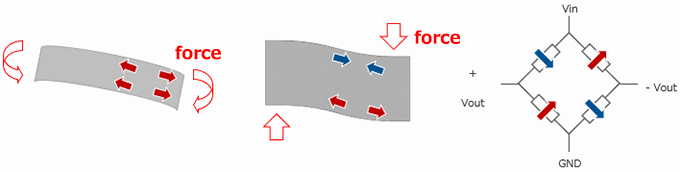

Like other strain sensor types, the change in resistance due to strain is minimal compared to the original resistance value. To extract this change, a Wheatstone bridge circuit is used to measure the difference in potential from the balance point.

- Chapter 2

- Strengths of Our Metallic Thin Film SensorsOur strong points

In this section, we will introduce the high-performance and unique features of our developed metallic thin film sensors.

Pursuing High Performance Potential and Convenience

1. High Sensitivity

- Our thin film materials have a gauge factor 5 to 10 times higher than typical metal foils. This high gauge factor allows us to achieve a high signal-to-noise ratio and enables high-sensitivity sensing for strain.

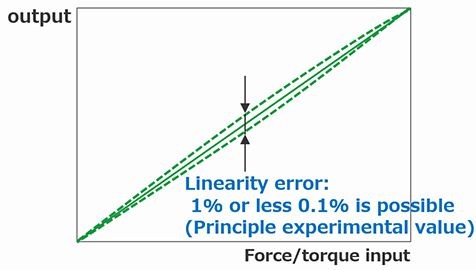

2. Excellent Linearity

- Our strain sensor elements are strongly bonded to the substrate via a rigid insulating layer, reducing the occurrence of hysteresis since there are no intervening sliding factors.

- Even within the linear elastic range of metals, our high-sensitivity strain sensor elements can detect slight strains, ensuring high linearity.

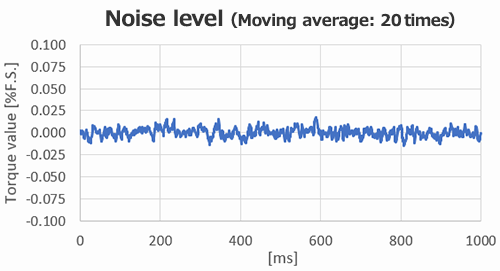

3. Low Drift

- Traditional film-type strain gauges have adhesive or resin materials between the strain gauge element and the substrate. Over time, environmental influences may cause these materials to deform, leading to drift. In contrast, our sensors are directly deposited on metal substrates, avoiding deformation of materials and making them less susceptible to environmental and temporal changes, resulting in reduced output drift.

4. High-Speed Response

- With minimal substances between the sensor and the substrate due to the direct deposition structure, inhibiting factors for response are minimized. As a result, the transmission speed from deformation is extremely fast, allowing for quick and accurate measurement of force and torque fluctuations.

5. High Durability

- Our direct deposition structure offers exceptionally high durability. Even after 10 million cycles of durability testing, the performance remains unchanged.

6. Easy Installation

- Our thin film strain sensors, which are directly deposited on metal chips, are mounted on the test object using a "screw-fastening" joining technique. This method allows for flexible structural design tailored to the device being installed, eliminating the need for time-consuming adhesion to the test object, making it suitable for mass production. This approach provides excellent stability and accurate strain measurement.

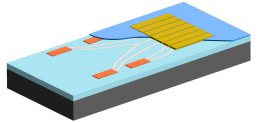

7. Design Flexibility

- The gauge pattern is achieved through the deposition process, allowing for pinpoint and fine patterns to be formed at the point of strain, making it possible to configure the thin film strain sensor according to the strain occurring in the customer's test object and enabling free design.

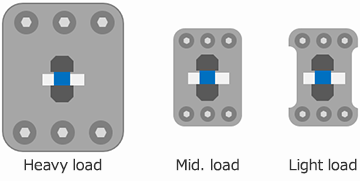

Providing Sensor Chips as Sensor Modules for Structures

By designing the elastic structure for attaching the sensor chip in the most suitable shape, we can achieve affordable force and torque sensors for a wide range of purposes, from heavy loads to microforces.

Elastic structure shape based on the measured load

- ※Please note that we provide sensor-chip-attached structures as sensor modules and do not offer sensor chips separately.

- and do not offer sensor chips separately.

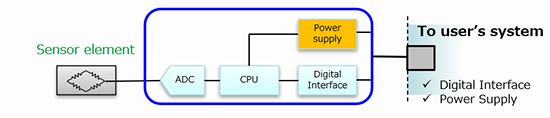

[Integrated Circuits avilable too]

- Please contact us for information on standard interfaces (standard is RS485, but also others such as RS422, EtherCAT, etc. available).

- ※Please contact us for information on standard interfaces (standard is

- RS485, but also others such as RS422, EtherCAT, etc. available).

- Chapter 3

- What Can Be Achieved with Thin Film SensorsWhat can be done with it?

Diverse Functional Possibilities

Our metallic thin film sensors can be used to achieve various functional needs. For example, you can:

- Measure the magnitude of forces and torques applied in one direction, ranging from very small forces to heavy load such as ton-class.

- Measure the magnitude of forces and torques applied in multiple directions, separately measuring each axis.

- Precisely control pressurized forces and rotational torques according to measured load.

- Detect and anticipate changes in loads to identify abnormalities or estimate the lifespan.

- Precisely measure weight.

- Instantly detect minimal movements.

- Convey the applied force to a person in a realistic way.

- Control equipment by adjusting the applied force.

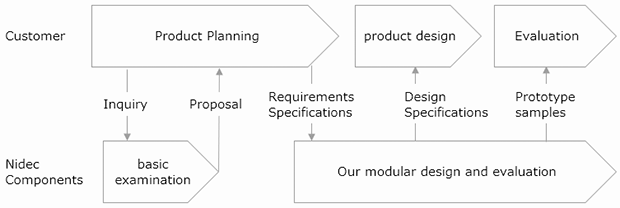

Please Share Your Requirements and Applications

From the above, our metallic thin film sensors are suitable for a wide range of applications.

To provide you with sensors that best suit your application's performance and usability, we propose sensors tailored to your specific needs. Effective collaboration in the early stages of development, including technical and specification alignment, is essential to deliver the sensor that best matches your product. Please feel free to consult with us.

Commercialization procedure