Pressure transducer P-8300

Double diaphragm structure P-8300

- Double diaphragm structure

- Two pressure references to choose from Gauge and Absolute

- Built-in temperature compensation function (0 ~ 50 °C)

Model Number Designation

| P-8300 - | 102 | A- | 05 |

|---|---|---|---|

|

Series name |

Rated pressure range 351:0 ~ 34.3 kPa {0 ~ 0.35 kgf/cm2} |

Pressure reference |

Thermal error |

List of model numbers

| Model Number | Rated pressure kPa{kgf/cm2} | Maximum pressure kPa{kgf/cm2} | Break-down pressure kPa{kgf/cm2} | Pressure reference | CAD |

|---|---|---|---|---|---|

| P-8300-501G-05 | 49.0 {0.5} | 98.1 {1} | 147 {1.5} | Gauge | |

| P-8300-501G-10 | 49.0 {0.5} | 98.1 {1} | 147 {1.5} | Gauge | |

| P-8300-102G-05 | 98.1 {1} | 196 {2} | 294 {3} | Gauge | |

| P-8300-102G-10 | 98.1 {1} | 196 {2} | 294 {3} | Gauge | |

| P-8300-352G-05 | 343 {3.5} | 686 {7} | 1030 {10.5} | Gauge | |

| P-8300-352G-10 | 343 {3.5} | 686 {7} | 1030 {10.5} | Gauge | |

| P-8300-103G-05 | 981 {10} | 1961 {20} | 2942 {30} | Gauge | |

| P-8300-103G-10 | 981 {10} | 1961 {20} | 2942 {30} | Gauge | |

| P-8300-351A-05 | 34.3 {0.35} (abs) | 103 {1.05} (abs) | 147 {1.5} (abs) | Absolute | |

| P-8300-351A-10 | 34.3 {0.35} (abs) | 103 {1.05} (abs) | 147 {1.5} (abs) | Absolute | |

| P-8300-102A-05 | 98.1 {1} (abs) | 196 {2} (abs) | 294 {3} (abs) | Absolute | |

| P-8300-102A-10 | 98.1 {1} (abs) | 196 {2} (abs) | 294 {3} (abs) | Absolute |

Standard specifications

| Operating temp. range | -20 ~ 70°C |

|---|---|

| Compensated temp. range | 0 ~ 50°C |

| Operating humidity | 35 ~ 85%RH(No condensation) |

| Storage temp. | − 20 ~ 70°C(Atmospheric pressure, humidity 65 %RH maximum) |

| Bridge resistance | 4700 ± 30 %Ω |

| Pressure medium | Corrosive gases/liquids compatible with SUS316L |

| Insulation resistance | 100 MΩ minimum (500 V DC) |

| Dielectric strength | 500 V AC, 60 s(Leakage current 1 mA maximum) |

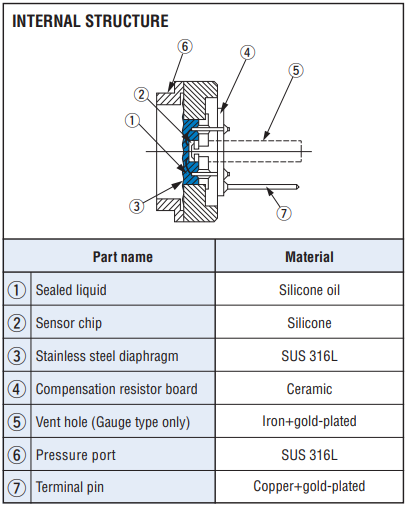

| Sealed liquid | Silicone oil |

| Net weight | Approx. 20g |

| Excitation current | 1.5mA DC(Constant current) |

Analog output

| Item | 501G | 102G | 352G | 103G | 351A | 102A | |

|---|---|---|---|---|---|---|---|

| Offset voltage | ± 5mV | ||||||

| Span voltage | 100 ± 50mV | ||||||

| Linearity/Hysteresis | ± 0.3%F.S. | ± 0.5%F.S. | |||||

| Thermal error (Reference temp.: 25 °C) | ZERO | ± 0.05/0.10%F.S./°C | |||||

| SPAN | ± 0.05/0.10%F.S./°C | ||||||

| Response | Approx. 2ms | ||||||

| Gravitational effect (From vertical position to horizontal position) |

Approx. 0.5%F.S. max. | Approx. 0.3%F.S. max. | Approx. 0.1%F.S. max. | Approx. 0.05%F.S. max. | Approx. 0.5%F.S. max. | Approx. 0.3%F.S. max. | |

Environment Characteristics

| Test item | Test conditions (At 25 ± 5 °C) | Permissible change |

|---|---|---|

| Vibration | 10 ~ 500 Hz, 1.5 mm maximum/98.1 m/s2 , 3 directions for 2 hours each |

Offset voltage/Span voltage: ± 1 %F.S. maximum each |

| Shock | 981 m/s2 , 3 directions for 3 times each | |

| Pressure cycling | 0 ~ Rated pressure, 106 cycles | |

| Moisture resistance | 40 °C, 90 ~ 95 %RH, 240 hrs |

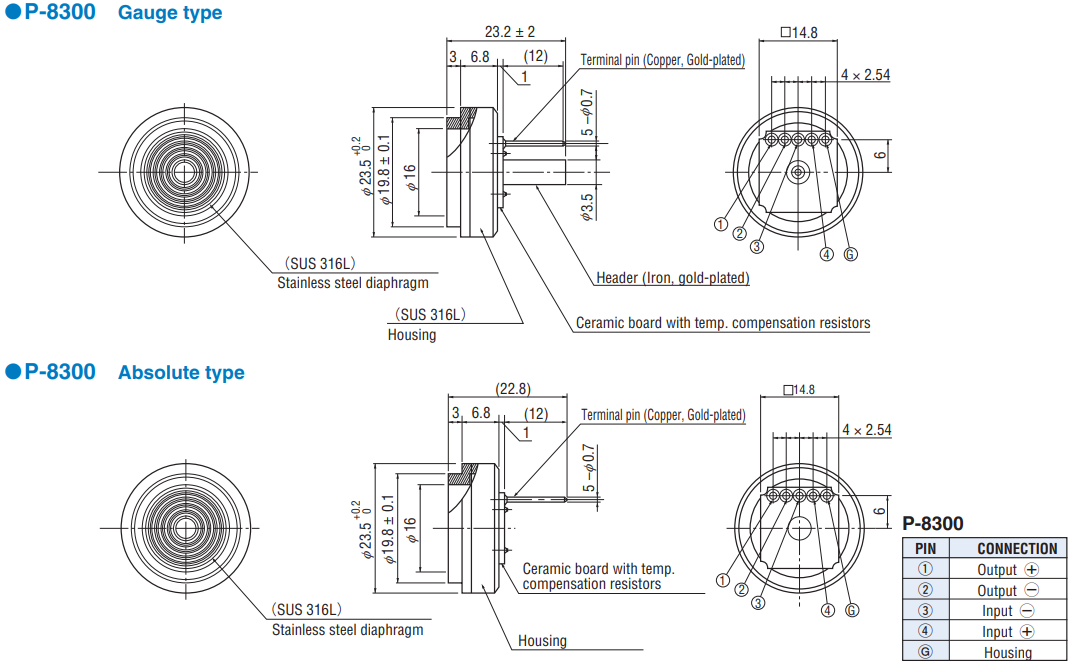

Outline dimensions

Unless otherwise specified, tolerance : ± 0.5 (Unit: mm)

-

Extra care should be taken with the diaphragm part. Do not touch the diaphragm directly to avoid damaging the diaphragm

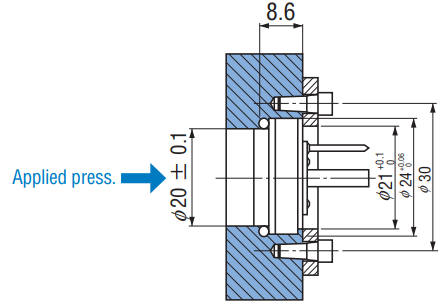

Installation example

- An “O” ring P20 (conforms to JIS B 2401 Material:Fluoro-rubber) is provided as accessory. Make the mounting bore diametersφ 24 andφ 20 ± 0.1, and the surface-roughness as 6.3 S ( ▽▽▽ ).

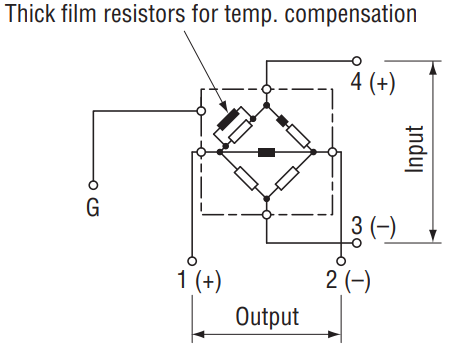

Internal electrical schematics

Documents

- ●The above contents and descriptions are subject to change without notice.