Trimmpotentiometer ST-4

- ●Um einen Kauf zu tätigen, wenden Sie sich an die Verteiler

oder nutzen Sie den stehenden Online-Shops unten.

Verkaufskanal Überprüfen Sie die Verteiler.- VERKAUFSKANALKlicken Sie hier, um den Verteiler zu überprüfen.

Surface Mount Cermet Trimmers (Single Turn)

- RoHS compliant

- Wide variety (7 types) to choose from

- Automatic mounting is possible (Taping)

- Flow/reflow soldering is possible

- Sealed construction (Washable)

- Stopper structure prevents terminal pin from being open.

- Cross slot rotor suitable for automatic adjustment

- In this series, chemSHERPA downloads are available,

which can be used for REACH-SVHC surveys, etc. - Click to go to the List of Part Numbers below for download

ELECTRICAL CHARACTERISTICS

| Nominal resistance range | 10 Ω ~ 2 MΩ |

|---|---|

| Resistance tolerance | ± 20 % |

| Power ratings | 0.25 W (70 °C), 0 W (125 °C) |

| Resistance law | Linear law (B) |

| Maximum input voltage | DC200 V or power rating, whichever is smaller |

| Maximum wiper current | 100 mA or power rating, whichever is smaller |

| Effective electrical angle | 210 ° (1 turn) |

| End resistance | 1 % or 2 Ω , whichever is greater |

| C.R.V. | 1 % or 3 Ω , whichever is greater |

| Operating temp. range | -55 ~ 125 °C |

| Temp. coefficient | 10 Ω ~ 50 Ω: ± 250 10-6/°C maximum 100 Ω ~ 2 MΩ: ± 100 10-6/°C maximum |

| Insulation resistance | 1000 MΩ minimum (DC500 V) |

| Dielectric strength | AC 500 V, 60 s |

| Net weight | Approx. 0.12 g (ST-4EA, EB, EC, ED, EF) Approx. 0.22 g (ST-4EG, EH) |

MECHANICAL CHARACTERISTICS

| Mechanical angle | 240° (1 turn) |

|---|---|

| Operating torque | 10 mN·m {102 gf·cm} maximum |

| Stop strength | 30 mN·m {306 gf·cm} minimum |

| Rotational life | 100 cycles [ΔR/R ≦ ± (2 Ω +3%)] |

| Thrust to rotor | 5 N {0.51 kgf} minimum |

| Solderability | 245 ±3°C, 2~3 s |

| Shear (Adhesion) | 5 N {0.51 kgf} 10 s |

| Substrate bending | Width 90 mm, bend 3 mm, 5 s, 1 time |

| Pull-off strength | 5 N {0.51 kgf} 10 s |

ENVIRONMENTAL CHARACTERISTICS

| Test item | Test conditions | Specifications |

|---|---|---|

| Thermal shock | -65~125 °C (0.5 h), 5 cycles | [ΔR/R ≦ 2%] [S.S. ≦ 1%] |

| Humidity | -10~65 °C (Relative humidity 80~98%), 10 cycles, 240 h | [ΔR/R ≦ 2%] |

| Shock | 981 m/s2, 6 ms 6 directions for 3 times each | [ΔR/R ≦ 1%] [S.S. ≦ 1%] |

| Vibration | Amplitude 1.52 mm or Acceleration 196 m/s2, 10~2000 Hz, 3 directions, 12 times each | [ΔR/R ≦ 1%] [S.S. ≦ 1%] |

| Load life | 70 °C, 0.25 W 1000 h | [ΔR/R ≦ 3 %] [S.S. ≦ 1 %] |

| Low temp. operation | -55 °C, 2 h | [ΔR/R ≦ 2%] [S.S. ≦ 2%] |

| High temp. exposure | 125 °C, 250 h | [ΔR/R ≦ 3%] [S.S. ≦ 2%] |

| Immersion seal | 85 °C, 60 s | No leaks (No continuous bubbles |

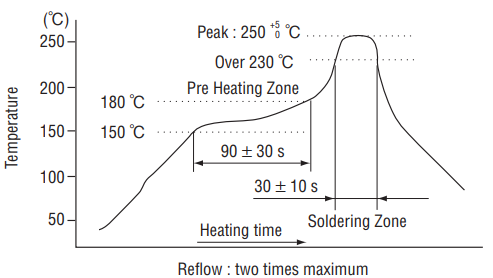

| Soldering heat | Flow : 260 ± 3 °C as the temperature in a pot of molten solder, immer sion from head of ter minal to backside of board, 5 ~ 6 s, two times maximum Reflow : Peak temperature 255 °C (Please refer to the profile below.) Manual soldering:350 ± 10 °C, 3 ~ 4 s |

[ΔR/R ≦ 1%] |

S.S.: Setting stability

〈Reflow profile for soldering heat evaluation〉

|

|

MAXIMUM INPUT RATINGS

| Nominal resistance values(Ω) | Resistance code | Maximum input voltage(V) | Maximum wiper current(mA) |

|---|---|---|---|

| 10※ | 100 | 1.00 | 100 |

| 20※ | 200 | 2.00 | 100 |

| 50 | 500 | 3.53 | 70.7 |

| 100 | 101 | 5.00 | 50.0 |

| 200 | 201 | 7.07 | 35.4 |

| 500 | 501 | 11.2 | 22.4 |

| 1k | 102 | 15.8 | 15.8 |

| 2k | 202 | 22.4 | 11.2 |

| 5k | 502 | 35.4 | 7.07 |

| 10k | 103 | 50.0 | 5.00 |

| 20k | 203 | 70.7 | 3.54 |

| 50k | 503 | 112 | 2.24 |

| 100k | 104 | 158 | 1.58 |

| 200k | 204 | 200 | 1.00 |

| 500k | 504 | 200 | 0.40 |

| 1M | 105 | 200 | 0.20 |

| 2M | 205 | 200 | 0.10 |

Part Number Designation

| ST-4 | E | T | A | 200 Ω (201) |

|---|---|---|---|---|

|

Series

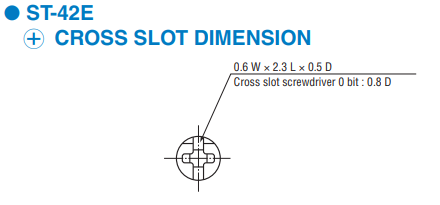

ST-4: ST-42: (Rotor groove) minus slot cross slot |

Terminal pins E: Sn-Cu (Lead-free) |

Packaging form T: Taping (Reel) Blank: Bulk in plastic bag |

Terminal shape (Adjust Pos.) A: J-hook (Top adjust) B: Gull wing (Top adjust) C: Through hole pins (Top adjust) D: Gull wing (Rear adjust) F: Through hole pins (Rear adjust) G: J-hook (Side adjust) H: Gull wing (Side adjust) |

Resistance value (Resistance code) |

List of Part Numbers

| Nominal resistance values | 10 Ω*, 20 Ω*, 50 Ω, 100 Ω, 200 Ω, 500 Ω, 1 kΩ, 2 kΩ, 5 kΩ, 10 kΩ, 20 kΩ, 50 kΩ, 100 kΩ, 200 kΩ, 500 kΩ, 1 MΩ, 2 MΩ |

|---|

| Part No. | Rotor groove | Terminal shape | Adjustment position | Packaging form | Packaging quantity | REACH-SVHC | CAD |

|---|---|---|---|---|---|---|---|

| ST-4ETA | minus slot | J-hook | Top adjust | Taping | 500 pcs./reel |

||

| ST-4EA | minus slot | J-hook | Top adjust | Bulk | 100 pcs./pack | ||

| ST-4ETB | minus slot | Gull wing | Top adjust | Taping | 500 pcs./reel |

||

| ST-4EB | minus slot | Gull wing | Top adjust | Bulk | 100 pcs./pack | ||

| ST-4EC | minus slot | Through hole | Top adjust | Bulk | 100 pcs./pack | ||

| ST-4ETD* | minus slot | Gull wing | Rear adjust | Taping | 500 pcs./reel |

||

| ST-4ED* | minus slot | Gull wing | Rear adjust | Bulk | 100 pcs./pack | ||

| ST-4EF※ | minus slot | Through hole | Rear adjust | Bulk | 100 pcs./pack | ||

| ST-4ETG | minus slot | J-hook | Side adjust | Taping | 500 pcs./reel |

||

| ST-4EG | minus slot | J-hook | Side adjust | Bulk | 100 pcs./pack | ||

| ST-4ETH | minus slot | Gull wing | Side adjust | Taping | 500 pcs./reel |

||

| ST-4EH | minus slot | Gull wing | Side adjust | Bulk | 100 pcs./pack | ||

| ST-42ETA | cross slot | J-hook | Top adjust | Taping | 500 pcs./reel |

||

| ST-42EA | cross slot | J-hook | Top adjust | Bulk | 100 pcs./pack | ||

| ST-42ETB | cross slot | Gull wing | Top adjust | Taping | 500 pcs./reel |

||

| ST-42EB | cross slot | Gull wing | Top adjust | Bulk | 100 pcs./pack | ||

| ST-42EC | cross slot | Through hole | Top adjust | Bulk | 100 pcs./pack | ||

| ST-42ETD* | cross slot | Gull wing | Rear adjust | Taping | 500 pcs./reel |

||

| ST-42ED* | cross slot | Gull wing | Rear adjust | Bulk | 100 pcs./pack | ||

| ST-42EF* | cross slot | Through hole | Rear adjust | Bulk | 100 pcs./pack | ||

| ST-42ETG | cross slot | J-hook | Side adjust | Taping | 500 pcs./reel |

||

| ST-42EG | cross slot | J-hook | Side adjust | Bulk | 100 pcs./pack | ||

| ST-42ETH | cross slot | Gull wing | Side adjust | Taping | 500 pcs./reel |

||

| ST-42EH | cross slot | Gull wing | Side adjust | Bulk | 100 pcs./pack |

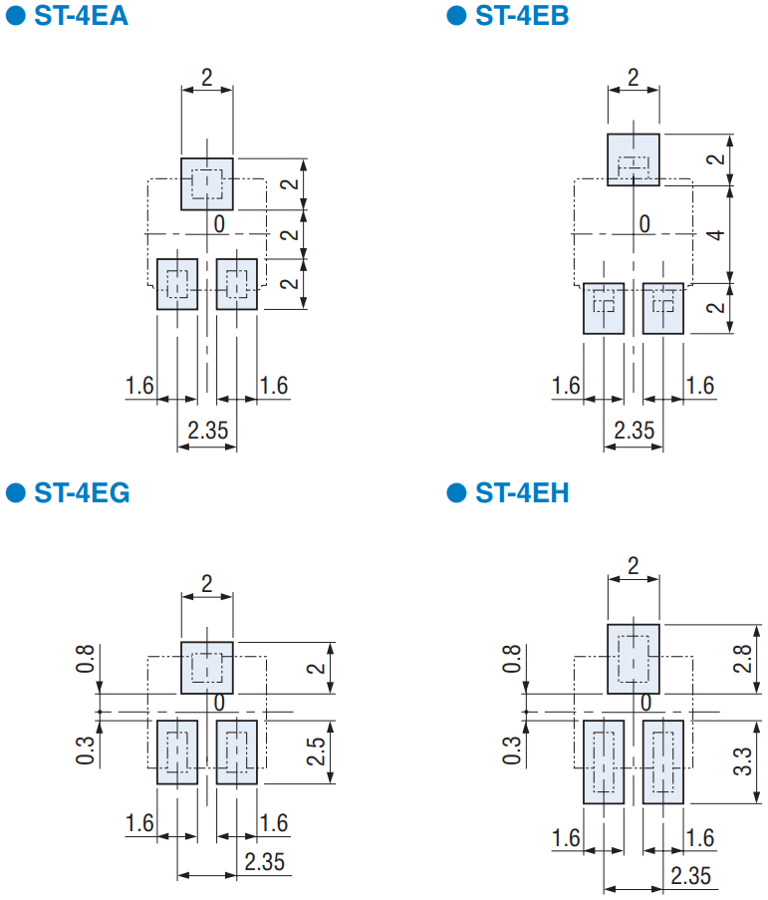

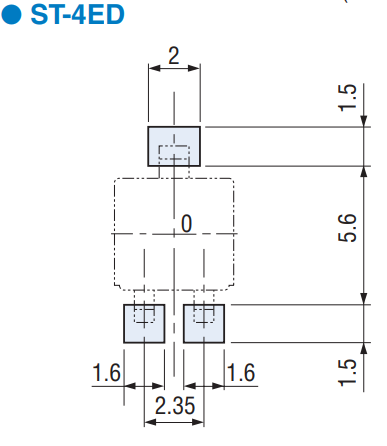

Recommended P.C.B. Pad Outline Dimensions

|

|

|

|

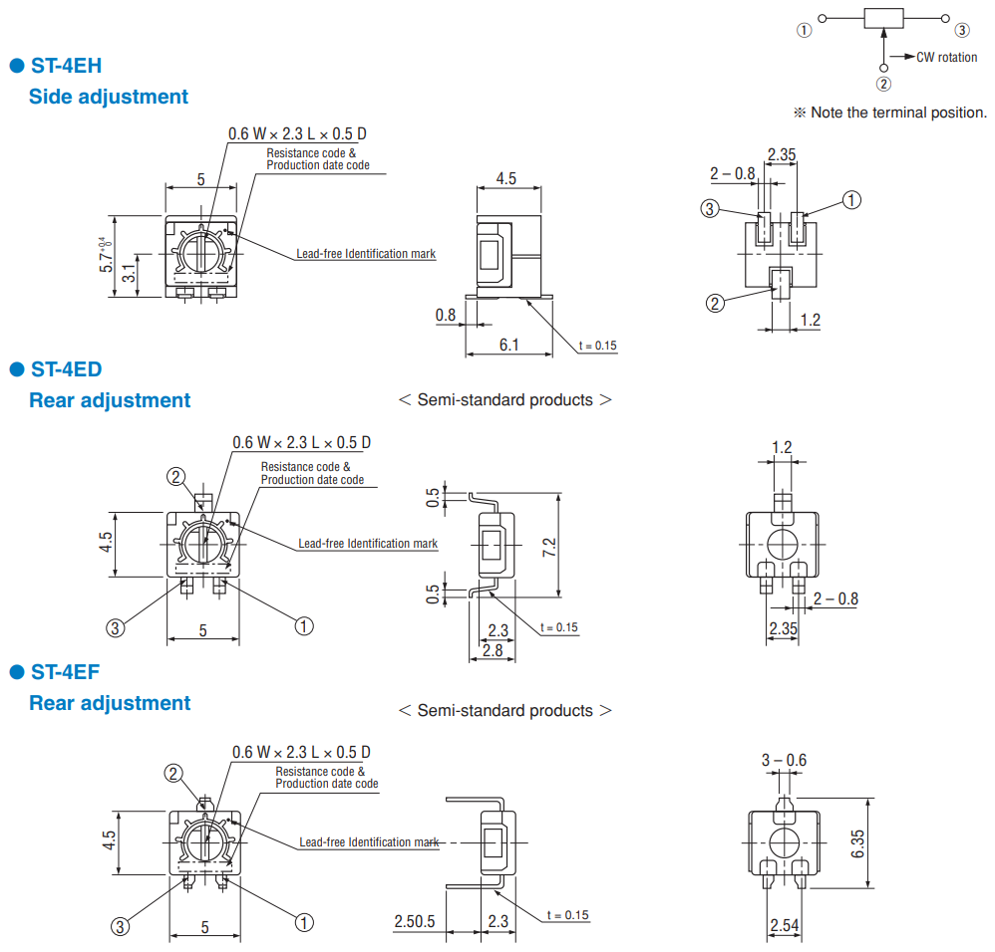

Outline Dimensions

Unless otherwise specified, tolerance : ± 0.3 (Unit: mm)

|

|

Unterlagen

Environmental Data

- ●Die oben genannten Inhalte können ohne vorherige Ankündigung geändert werden.